Coils

Coils, known for durability, versatility, and strength, are widely used in construction, manufacturing, household goods, and industrial machinery applications.

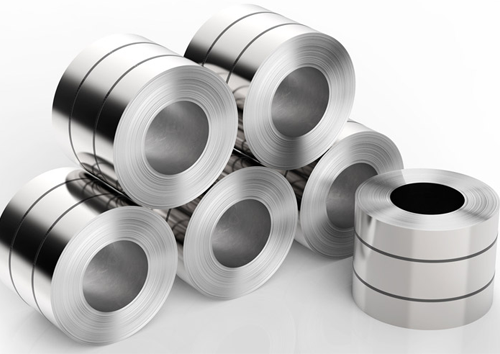

Steel Coil

Unlike other steels, stainless steel coils do not corrode, rust, or discolor easily when exposed to water. Stainless steel coils are utilized in several applications.

Types of Coils:

Grades as per your size requirements: Grade 904L,

254 SMOⓇ,

Duplex,

Super Duplex,

Alloy 825

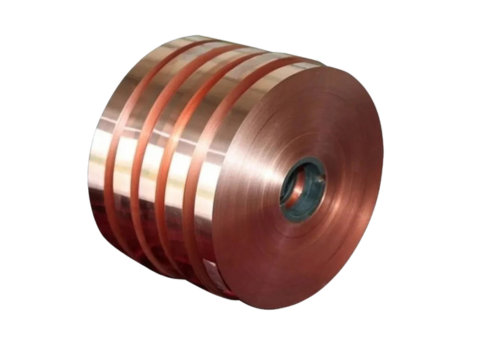

Copper Coil

Copper coils offer high conductivity, durability, and resistance to corrosion, while also being recyclable and eco-friendly. Cost-effective and low-maintenance, copper is easily shaped for varied uses, with coils widely applied in automobile alternators and generators.

Types of Copper Coils:

CDA 101, 102 OFHC

CDA 107 Silver Bearing OFHC

CDA 110 Electrolytic Tough Pitch

CDA 113, 114, 117 Silver Bearing

CDA 122 DHP

CDA 145 Tellurium Copper

CDA 150 AMZIRC, Zirconium Copper

CDA 162 Cadmium Copper

CDA 172, 173, 175, 17510 Beryllium Copper

CDA 182 Chromium Copper

CDA 187 Leaded Copper

CDA 194, 195 Iron Bearing Copper

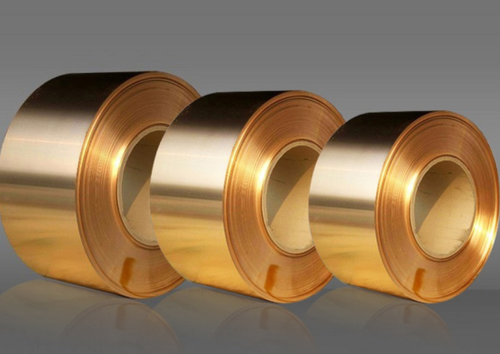

Brass Coil

Brass coils, made from copper and zinc, combine conductivity, corrosion resistance, and durability, making them ideal for electrical components. Lightweight, malleable, and ductile, they can be precisely shaped, cut, and sized for diverse applications.

Types of Brass Coil:

CDA 210 Guilding Brass

CDA 220 Commercial Bronze

CDA 230 Red Brass

CDA 240 Rich Low Brass

CDA 260 Cartridge Brass

CDA 268, 272 Yellow Brass

CDA 280 Muntz Metal

CDA 314 Leaded Commercial Brass

CDA 330 Low Leaded Tube Brass

CDA 353, 356 High Leaded Brass

CDA 360 Free Cutting Brass

CDA 464 Naval Brass

CDA 482, 485 Leaded Naval Brass

Bronze Coil

Bronze coils, made from copper and tin, are strong, corrosion- and fatigue-resistant, and excellent heat/electricity conductors. Durable and low-maintenance, they are widely used in electronics, automotive, and marine industries, with added resistance to saltwater. Environmentally friendly, bronze coils can be recycled without losing strength or conductivity.

Types of Bronze Coil:

CDA 510 Grade "A" Phosphor Bronze

CDA 511 Phosphor Bronze

CDA 521 Grade "C" Phosphor Bronze

CDA 544 B-2 Phosphor Bronze

CDA 630 Nickel Bearing Aluminum Bronze

CDA 642 Aluminum Silicon Bronze

CDA 651, 655 Silicon Bronze

CDA 675 Manganese Bronze

CDA 706 Cupro-Nickel 10%

CDA 715 Cupro-Nickel 30%

CDA 725 Cupro-Nickel

CDA 752, 762, 770 Nickel Silver

CDA 932 Bearing Bronze

CDA 954 Aluminum Bronze

Application of Coils

Unlike other steels, coils do not corrode, rust, or discolor easily when exposed to water. Coils are utilized in several applications.

-

Aerospace

-

Defense

-

Chemical Processing

-

Oil and Gas

-

Transportation

-

Electrical Energy

-

Medical

-

Automotive

-

Food Preparation Equipment

-

Appliances

-

Construction

-

Mining

-

Electronics